SHELVING – AN OVERVIEW

A survey and analysis by High Density, Inc. will yield various storage options and unique designs for your application and facility.

Generally, what might be termed the “best” solution is arrived through considering:

- The layout of your unique space, floor composition and building structure

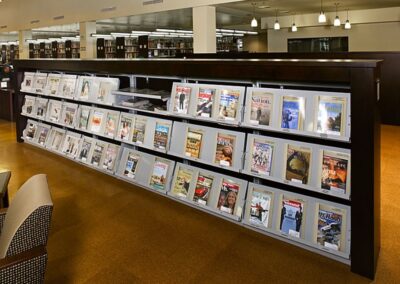

- A detailed Inventory of the types of items and commodities you will be storing and the frequency of access

- Projected growth and plans to account for it

- Security requirements for the files or commodities stored

- Local building, fire, and ADA codes

- Weight load of individual items and the number needing to be stored on each shelf/storage levels. This determines the needed shelf capacity. Note: that this capacity is based upon evenly distributed loads.

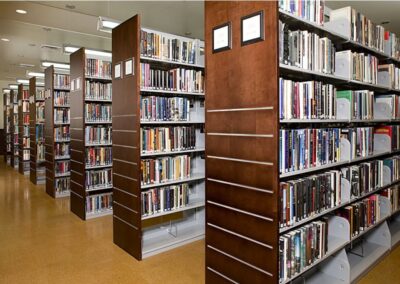

- Determine height of shelving needed. Ceiling height and number of shelf openings required can help determine the height needed. Shelf openings are the space between shelf levels. Remember to measure your product height when determining your shelf opening size.

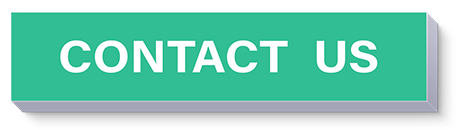

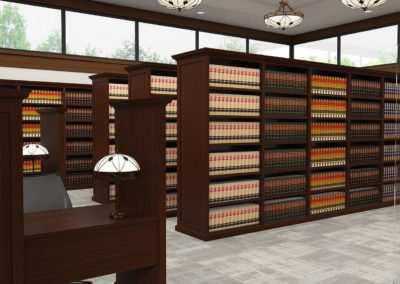

- Aesthetics and how the storage/shelving system looks to your employees or customers

Getting the right storage system that works best for your space and application can be achieved through calling HDI today. Getting what works best for you, is far different than working with what you get.

STORAGE PLANNING GUIDELINES

- Planning is the key to successful storage operations. Planning a space-efficient facility that also accounts for the staff and their functions and such key points as where the receiving, staging shipping locations are, and the location of key manager’s area to be located impact the design success of the facility.

- Review the available types of space saving shelving and equipment that may help you optimize your space before settling on standard static shelving. Also, consider ways you could build up to increase your use of vertical space before investing in add-ons or building a new storage room.

- To quickly and efficiently design a layout, ignore existing obstructions.Draw your initial shelving layout as if there are no columns or obstructions present in your building. After you’ve designed the most efficient layout for your space, then draw in the columns and obstructions and adjust your initial, highly efficient layout as little as possible to accommodate obstructions. Of course, there are always floor space obstructions.

- Arrange racks in long rows as possible rather than short rows to maximize space.You may feel you have all the space in the world, but the reality is physical constraints, aisles, and code compliance quickly limits usable space.

ABOUT US

HIGH DENSITY INC 2023 ALL RIGHTS RESERVED